Soldering —also known as sweating—is a foundational skill in plumbing, and one that opens the door to professional-quality copper piping repairs and installations.

In this introductory guide, we’ll explain the basics: what soldering is, when and why to use it, and how to do it safely and effectively. By the end you’ll be ready to solder your first pipe using our step-by-step guide!

Introduction to Soldering in Plumbing

What Is Soldering?

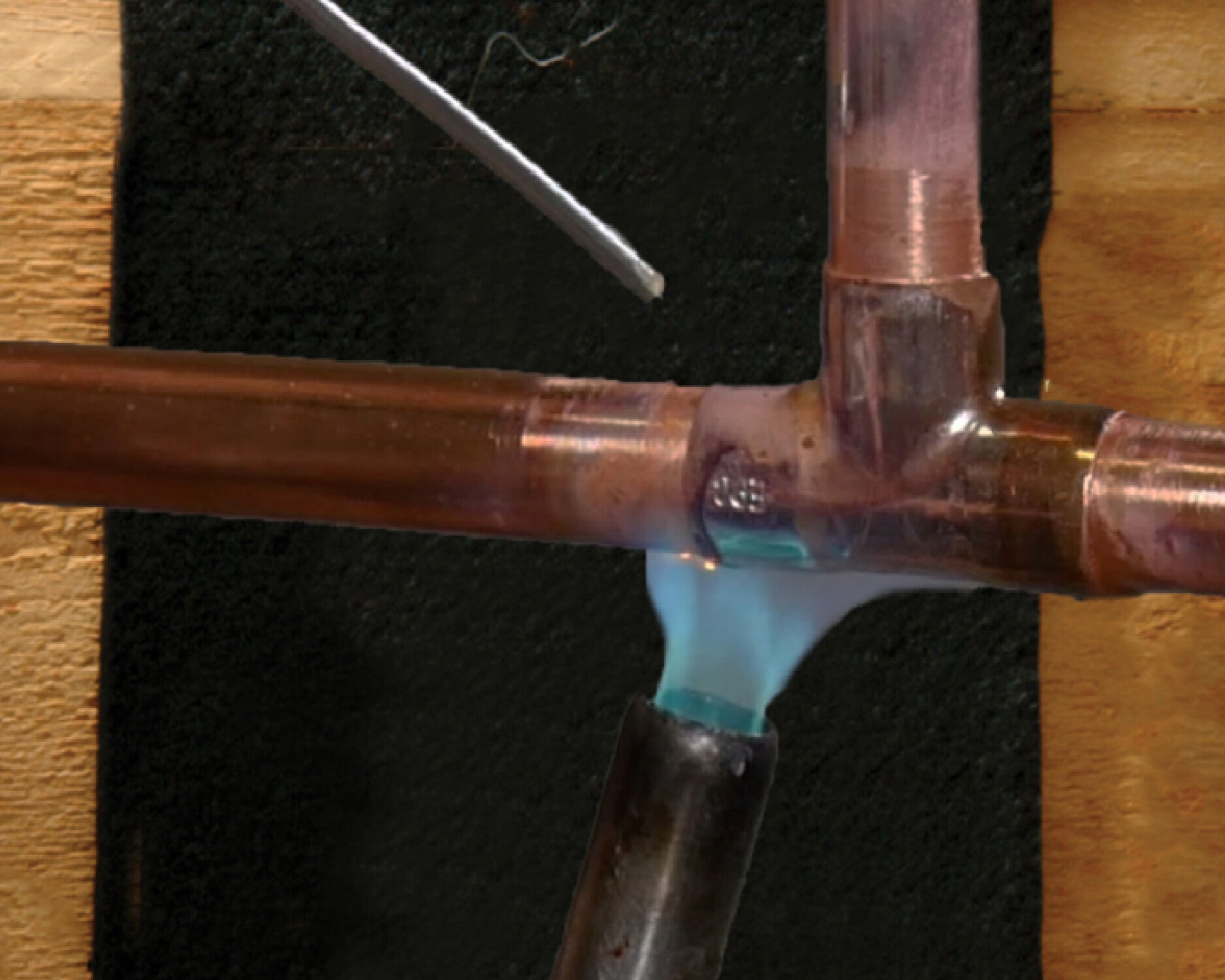

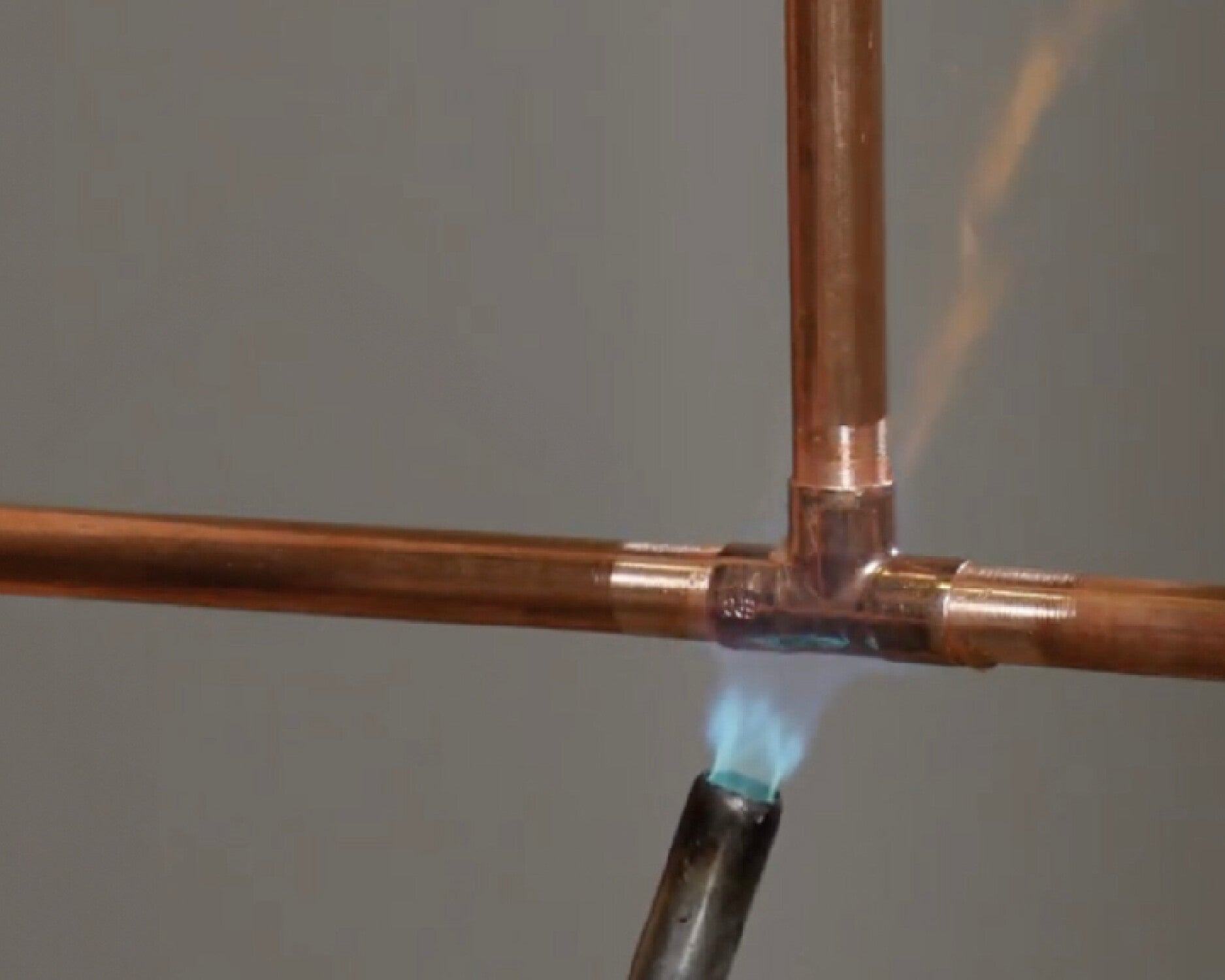

Widely used in plumbing, HVAC, electronics, and even craftwork, soldering is a time-tested method for joining copper pipe and fittings using heat and a filler metal (solder). Heat is applied to a joint between two metal parts—typically copper pipes and fittings—so the filler metal (solder) can flow into the joint and create a watertight seal.

What is Solder?

Solder is an alloy of different types of metals, which change depending on the application. Traditionally, solder was made from lead. However, since regulatory bodies have become aware of the adverse effects of lead in potable water systems, we no longer use lead solders for potable water applications. Nonetheless, lead solder is still used and preferred in some applications.

Solder is used on many materials, including brass, copper, and galvanized steel.

Soldering 101: What Beginners Need to Know

Key terms:

- Solder: A metal alloy that melts at a relatively low temperature and forms the joint between metals.

- Flux: A chemical agent applied to pipe and fittings before heating to clean metal surfaces and help the solder flow.

- Sweating: A plumber’s term for soldering copper pipe.

- Deburring/reaming: Removing the inner burrs after cutting copper pipe to restore full flow and reduce potential clogs. Burrs are small, rough edges or projections that remain on the surface of a material after it has been cut, machined, or otherwise processed.

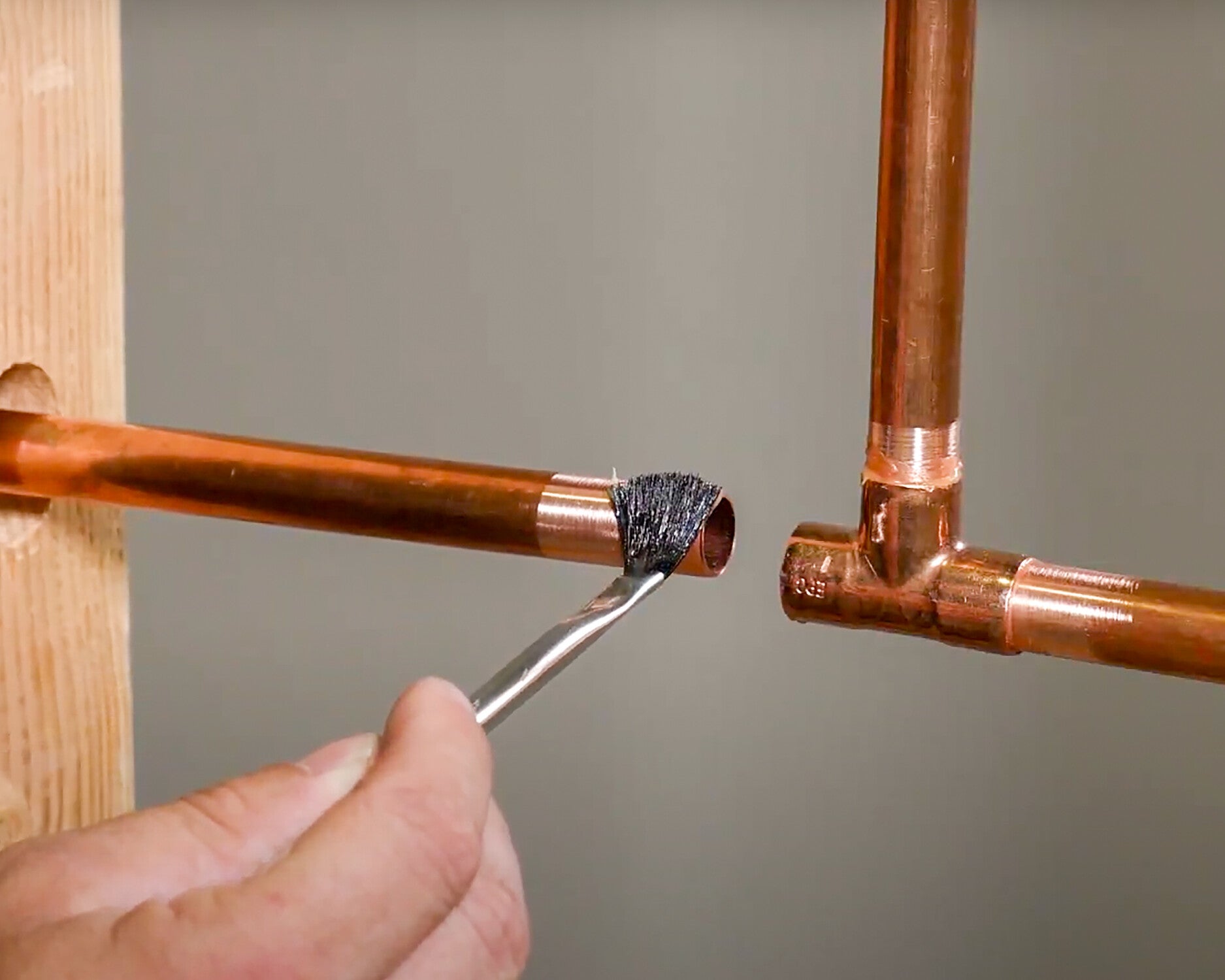

- Pipe and fitting prep: The process of cleaning both the pipe and the fitting, using sand cloth or a fitting brush to remove oxidation and debris before applying flux.

- Acid brush: A small brush made from 100% pure stiff horse hair, tiled with a steel staple and used to apply flux.

When and Why You Should Use Solder

Soldering Applications & Types

Soldering remains a preferred method in several applications:

- Plumbing/potable water: Solders made from lead-free alloys are used for potable water systems.

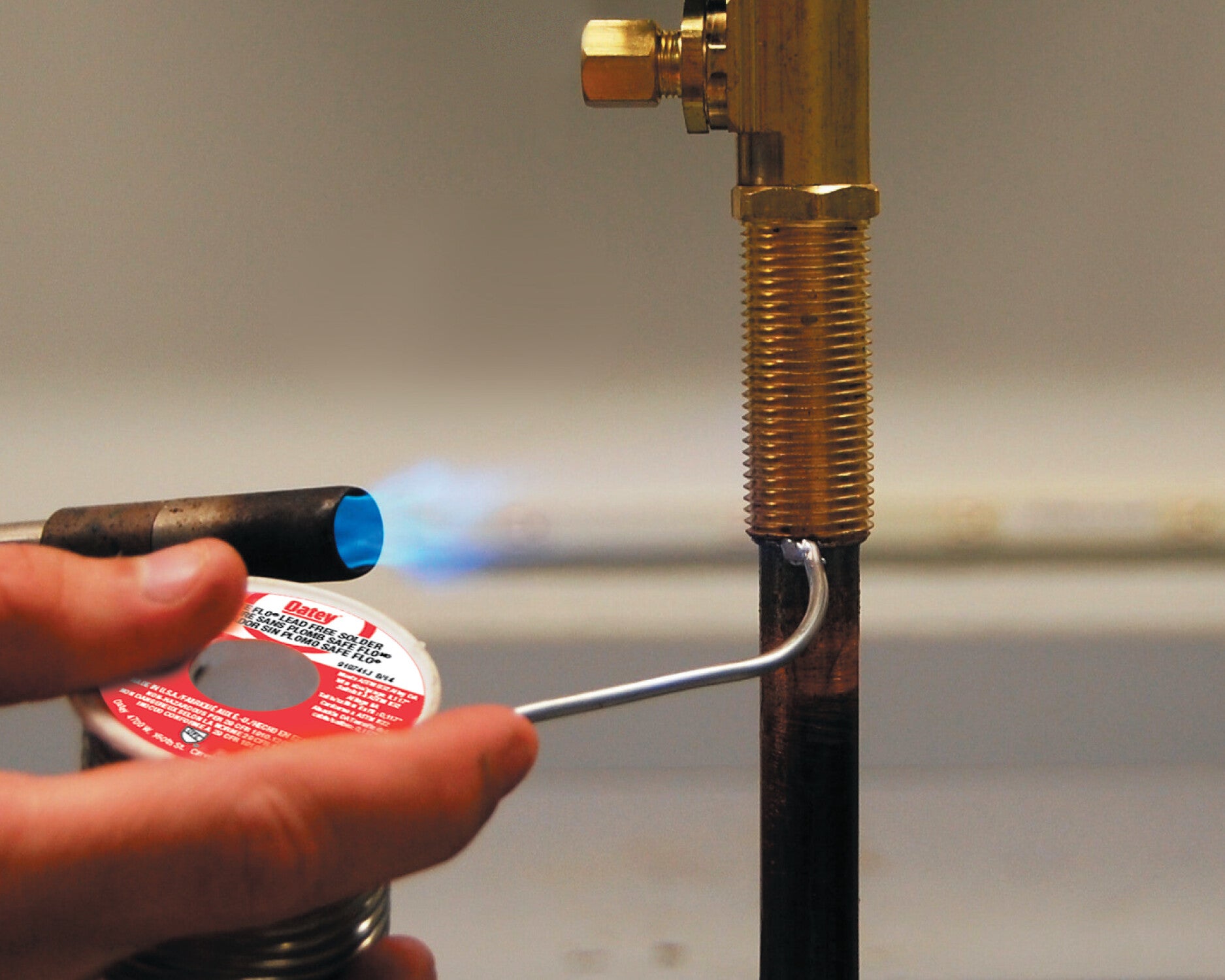

The best solder for copper pipes: We recommend the Oatey® 95/5 and the Oatey® Safe-Flo® solders. Both are 100% lead-free and, therefore, suitable for drinking water applications, refrigeration lines, or cooling equipment. Oatey® 97/3 is a tin-copper alloy. Due to its higher melting point, this combination is perfect for sweating copper and brass plumbing joints. - Galvanized steel and electrical work: Oatey® Acid Core Wire Solder and Oatey® Rosin Core Wire Solder are 2-in-1 solutions that combine the solder with an acid or rosin flux core. These hybrids are typically used for general-purpose repairs. Acid core solder is perfect for repairing galvanized gutters and filling metal seams. Rosin core solder is used in electrical applications, including wiring and other fine electronic work.

- Tin plating, seaming joints, and sheet metal repair: Oatey® Wire Solder or Oatey® Bar Solder is commonly used for tin plating, seaming joints, and sheet metal repair.

- HVAC: For copper tubing in heating/cooling systems.

- Crafting: Oatey® Instant Solder products are often used in jewelry making and small-scale repairs.

Read more in our blog: What Are the Different Types of Solder

Why Solder?

Soldered joints are not only more compact and better suited for confined areas, but they also eliminate reliance on internal mechanisms that can fail if improperly installed.

Additionally, fittings for soldering tend to be more affordable than those for press systems, making them ideal for projects that involve multiple joints. When completed effectively, soldered joints offer a more permanent feel, resulting in long-lasting, leak-resistant connections. This method is especially appealing for DIYers looking to avoid expensive tools like ProPress.

While technologies like push-to-connect fittings and press systems have gained popularity, soldering, when executed correctly, provides superior control in tight spaces, lower fitting costs, and strong mechanical bonds.

The Role of Flux for Soldering Copper Pipes

Flux cleans and protects joints from oxidation, ensuring even solder flow. It's vital for strong, leak-free connections, similar to applying primer before painting.

Oatey offers several options, including Oatey® No. 95 Tinning Flux and Oatey® H-20 Water-Soluble Flux.

For more information on making the right flux selection, read: Choosing the Right Flux for Soldering Copper Pipes

Soldering Tools

Basic plumbing solder tools include:

- Solder and flux

- Deburring tool

- Torch (sized appropriately for pipe diameter) and fuel

- Acid brush for flux application

- Fitting brush and sand/mesh cloth

- Pipe/tubing cutters

- Damp rag

- Flame Protector

- PPE: gloves, eye protection, fire extinguisher

Safety Tips for Soldering Copper

Always follow these safety instructions when soldering:

- Always wear heat-resistant gloves, safety goggles, long sleeves, and closed-toe shoes.

- Use an Oatey® Flame Protector to shield nearby materials (especially wood or flammable materials).

- Keep a fire extinguisher nearby.

- Double-check your surroundings before and after applying heat.

- Never solder directly above your head—hot solder drips!

- Always check for smoldering materials after soldering.

Soldering Techniques

Preparing Pipes and Fittings

To ensure optimal flow and prevent restrictions, start by cleaning the pipe's exterior using sand cloth or abrasive mesh. Next, clean the interior of the fittings with a fitting brush. Finally, deburr the ends of the pipe with a copper reaming tool to achieve a smooth finish.

Applying Flux: Best Practices

- When soldering pipes, it’s important to use a thin layer of flux on both the pipe and the fitting, ensuring that any excess is wiped off after assembly.

- Avoid overheating the joints, as this can burn off the flux and compromise the seal.

- For those working with large-diameter pipes or for beginners, using tinning flux, such as Oatey No. 95/5, is recommended, because it contains embedded solder that improves coverage. Alternatively, for easier cleanup, especially when working with drinking water lines, H2O flux is a good choice as it is water-soluble and helps reduce any residual taste and odor.

- Tinning fluxes like No. 95 Tinning Flux are particularly beneficial for beginners and for making large-diameter joints, rendering the process more manageable.

How to Avoid Common Soldering Mistakes

- Don’t choose the wrong products.

- Don’t skip the prep.

- Protect the surrounding areas.

- Don’t apply too much.

- Don’t overheat the joint.

- Don’t neglect the cleanup.

Read: Six soldering mistakes to watch out for and tips for doing it right.

Fast Fixes and Small Applications

These products are great to keep on hand for weekend DIYs or temporary patches.

- Oatey® Instant Solder: Combines flux and solder for quick, clean fixes

- Oatey® Fix-It™ Stick: Temporary epoxy putty for emergency pipe repairs

Now that you understand the basics, take the next step: Learn how to solder copper pipes like a pro.

Frequently Asked Questions

-

Can you solder without flux?

-

No. Flux is essential—it cleans, prevents oxidation, and draws solder into the joint.

-

-

What solder is safe for drinking water?

-

Use a lead-free option like Oatey Safe-Flo®.

-

-

How long does a soldered joint last?

-

A properly soldered joint can last decades, but like all mechanical connections, it may fail if installed improperly.

-

-

What is instant solder used for?

-

It’s excellent for fast fixes and crafts. It combines flux and solder in one application and is suitable for small-diameter pipe (½-inch to ¾-inch).

-

-

Can I use a Fix-It Stick instead of soldering?

-

Fix-It Stick is a temporary repair epoxy, not a long-term solution. It can help in emergencies, but should be replaced with a permanent repair.

-