Solvent welding is an essential plumbing technique used to chemically fuse PVC, ABS, or CPVC pipes and fittings. In this blog post, we will guide you through the eight steps of how to solvent weld, including tips and resources to get the perfect solvent weld every time.

Step 1: Square Pipe Ends, Chamfer, and Remove Dirt.

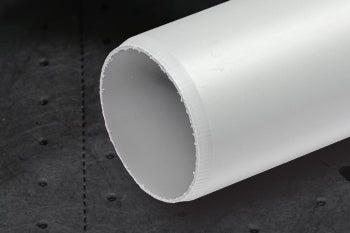

The first step to achieve a perfect solvent weld is to cut the pipe to the desired length. It is vital that the cut be straight and clean, as the joint's quality depends on it. A square pipe ensures maximum surface area to create fusion and joint strength, ensuring the strongest bond.

Leave a slight chamfer on the edge of the pipe to allow for proper insertion and fusion with the fitting. We recommend a 10% to 15% chamfer, but the main objective is to eliminate the sharp edge. If you don’t chamfer the pipe or bevel the outside edge, the sharp edges can scrape the solvent cement off the walls of the fitting as the pipe is being inserted. This could potentially cause a blockage or leak paths.

Step 2: Deburr the pipe

Next, deburr the pipe, smoothing its rough edges. If you don’t deburr, pieces of plastic can break free and move through the system, leading to blockages in items like aerators. Burrs can also catch certain types of debris, which could also eventually lead to a blockage.

Step 3: Dry-Fit the Pipe and Fitting

Sometimes referred to as the interference fit, join the pipe and fitting together without applying any solvent cement. Make sure the pipes align and fit correctly. Dry-fitting is done to ensure there is enough resistance in the joint. This helps create the chemical bond between the pipe and the fitting. If the joint bottoms out, you do not have an interference fit. If any issues arise, now is the time to address them, as it is difficult to make any changes after the cement is applied.

Step 4: Clean the Pipe and Fitting

Clean both the pipe and fitting thoroughly with an ABS, PVC or CPVC cleaner. Applying a cleaner will prepare the surfaces for the cement, ensuring your solvent weld is strong by removing any dirt, debris, or oils. Oatey offers a range of cleaners and primers that are specifically designed to ensure excellent results.

For example, Oatey® Clear Cleaner is a fast-acting solution that removes surface dirt, grease, and grime. It is formulated for all schedules and diameters of ABS, PVC and CPVC pipe and fittings. Its clear finish flows freely, evaporates quickly, will not stain most surfaces, and applies easily with its included in-lid dauber.

Step 5: Apply Primer

Before the cementing process can begin, apply PVC, ABS or CPVC primer. Not only does primer remove surface dirt, grease and grime, but solvents within the primer itself soften the pipe, dissolving into and separating the pipe’s surface molecules. As a result, the surface becomes more porous, allowing for a fast and secure solvent weld.

We recommend applying the first coat on the fitting and then the pipe. Follow up with a second coat on the fitting, redipping the applicator between each coat. This ensures you generously cover the area with primer to soften the fitting’s insides before solvent welding. Wait no longer than 5 minutes before adding cement.

If you are using ABS pipes, do not apply primer to the pipe and fitting. We recommend using Oatey® Clear Cleaner for ABS pipes and fittings

Step 6: Apply Solvent Cement

Once your primer has dried, apply a thin coat of solvent cement to your joint. To do this, we recommend first applying the cement to the pipe and then to the fitting. Finally, apply the solvent cement to the pipe once more, redipping into the cement after you've applied it. Be sure to avoid puddling the cement, which can cause weakening and premature failure of the pipe or the fitting.

For a close look at Oatey primer and solvent cement products, check out our Oatey 101 blog on Solvent Cements and Primers.

Step 7: Quickly Join the Pipe to the Fitting

Next, you will want to quickly insert the pipe into the fitting, giving it a quarter turn and holding it firmly for at least 30 seconds before it sets. This quarter turn is essential to achieve a secure, leak-proof joint. It also ensures the cement spreads evenly. We recommend you wipe off any excess cement, which, if left for too long, can affect cure times.

Step 8: Allow Time to Cure

Once you have connected the joint, allow ample time for the cement to cure completely. Cure times depend on four key factors:

- Humidity: For humidity over 60%, increase the curing time by 50%; for example, a one-hour cure time would become 1.5 hours.

- Material: PVC and ABS cure quicker than CPVC because the solvents in the cement and primers penetrate further into CPVC pipes and fittings.

- Size: Larger-diameter pipes take longer to cure. Allow extra time for pipes above three inches in diameter.

- Temperature: Generally, for temperatures above 60° Fahrenheit, we recommend a two-hour cure time before pressure testing up to 180 psi (pounds per square inch).

To find the specific cure time for your project, check out our comprehensive guide for Solvent Welding Curing Times.