Did you know that the strongest part of a plumbing system, when properly solvent cemented, is the bonded joint? That’s because, when you join pipes and fittings, you aren’t just gluing them together. While you might hear solvent cements referred to as glue, solvent cements actually soften and chemically fuse pipe and fittings together, creating one piece rather than two pieces simply stuck together. Solvent cement can easily and quickly fuse PVC, ABS and CPVC pipes, if properly executed. There are several steps to complete before applying the solvent cement that are crucial to achieving a long-lasting and durable connection.

Pipe Types

ABS: Acrylonitrile Butadiene Styrene

• Typically used for non-pressure piping applications.

CPVC: Chlorinated Poly Vinyl Chloride

• Typically used for pressure piping applications, including hot and cold potable water distribution. Can also be used for corrosive fluid handling in industrial or chemical applications.

PVC: Poly Vinyl Chloride

• Typically used for pressure or non-pressure piping applications.

What You'll Need For This Project

• Pipe (See pipe types below)

• Fitting hub

• Solvent cement

• Pipe cleaner

• Primer, if cementing PVC or CPVC pipe and fittings

• Plastic pipe cutter

• File or chamfering tool

Step 1. Cut and deburr the pipe

Your pipe must be cut square. Once cut, deburr and chamfer both the inside and outside of the pipe ends using a file or chamfering tool.

Be sure to remove all dirt as well.

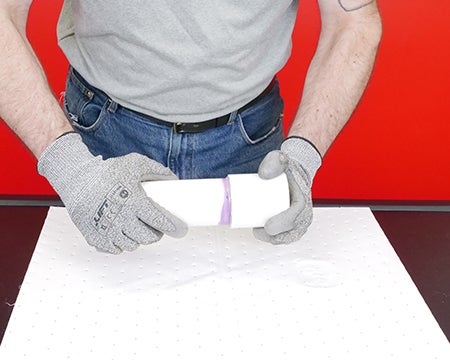

Step 2. Ensure that pipe and fitting hub fit

Dry fit together the pipe and fitting hub to ensure a smooth fit.

Tip: The pipe should easily go one-third to two-thirds of the way into the fitting hub.

Step 3. Clean pipe and fitting hub

If working with an existing pipe, use a listed cleaner to clean the pipe and fitting hub. Apply the cleaner in a clockwise motion around both parts. This will ensure a stronger connection.

Note that cleaner is not required on brand new pipes. Simply wipe away any surface dirt with a rag.

Tip: Oatey has a variety of cleaners that can quickly remove dirt, grease and grime.

Step 4. Apply primer

If working with PVC or CPVC pipe and fittings, apply primer inside the fitting hub, then to the exterior of the pipe end and once again inside the fitting hub.

Important: Re-dip dauber back into primer after each application.

Tip: Do NOT use primer on ABS pipe and fittings.

Step 5. Apply cement

Apply a liberal coat of cement to the exterior of the pipe end. Make sure to apply beyond the fitting hub depth.

Next, apply the cement inside the fitting hub. Finally, re-dip the dauber back into the cement and apply to the outside of the pipe end.

Important: Apply cement within five minutes of priming.

Tip: Stir or shake cement before using.

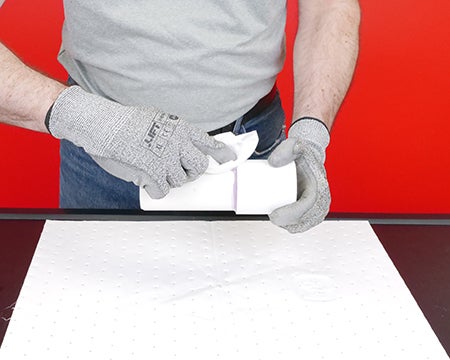

Step 6. Connect pipe and fitting

Insert the pipe into the fitting hub, turning the pipe one-quarter of a turn as you push the pipe end into the fitting.

Make sure the pipe end bottoms out inside the fitting hub and hold for 30 seconds to prevent push-out.

Lastly, wipe off any excess cement that may squeeze out.

Important: Assemble parts QUICKLY. The cement must be fluid. Dried cement CAN NOT be re-coated.

Step 7. Allow cement to cure before testing

Click here for specific cure times.

Remember, DO NOT TEST WITH COMPRESSED AIR OR GAS.

Tip: Lower temperatures and larger diameter pipes may need a little extra hold time.

There are a variety of cements for every job. Not sure what to choose? See our blog post to help you pick the perfect cement to get your project done right.