How to Keep a Well-Maintained Hydronic Heating System with Hercules Heating Chemicals and Antifreeze Products

A well-maintained hydronic heating system provides reliable performance even during the harshest winters. Heating maintenance professionals know that top quality materials are critical to achieving superior performance. That is why contractors depend on Hercules Maintenance and Stop-Leak Products. They are formulated for high performance and developed with both the user and the environment in mind.

What You'll Need For This Project

Step 1. Clean the System

It is recommended that any system, whether new or existing, be thoroughly cleaned prior to being charged with Cryo-Tek products. Any system contaminated with dirt and other materials reduces efficiency and wears the system prematurely. New systems need to be free of flux, solder residue, grease and any foreign particles.

Most boiler manufacturers recommend cleaning new systems with a solution of Tri-Sodium Phosphate (TSP), or Hercules Boiler and Heating System Cleaner (follow instructions on container). Existing systems need to be flushed and cleaned to eliminate any build-up of rust, scale, lime and other non-organic matter.

These systems should be cleaned with an inhibited hydrochloric acid such as Hercules Sizzle (except aluminum systems, check with boiler manufacturer). All systems should be checked for leaks prior to installation of any Cryo-Tek product.

.png)

Step 2. Measure the Total Capacity of the System

Measure the total capacity of your heating system so you know exactly how much product to add to your system. You can measure the capacity of your system one of two ways – the Direct or Estimation method:

Direct Method

- Fill system completely, making sure all components of the system are full.

- Shut the system down and let the pressure drop to a safe level.

- Drain out fluid into a suitable container and record the number of gallons removed. This is TOTAL SYSTEM FLUID CAPACITY.

Estimation Method

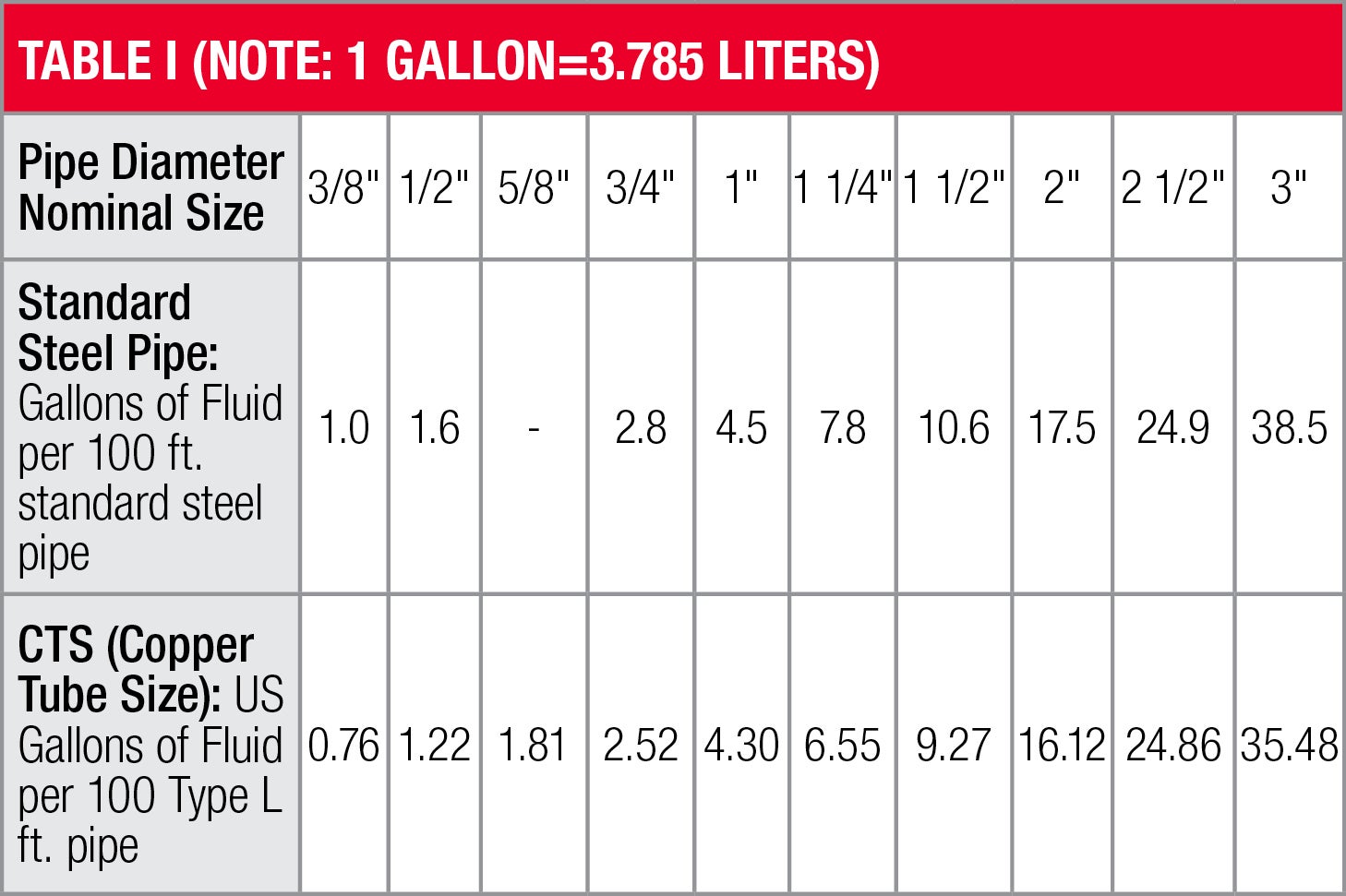

- Determine system pipe sizes and amount of linear footage for each size. Using Table I, calculate the volume of the system piping.

- Add this number to the gallon capacity of the boiler or equipment in the system to determine the TOTAL SYSTEM FLUID CAPACITY.

Step 3. Select Desired Temperature Coverage

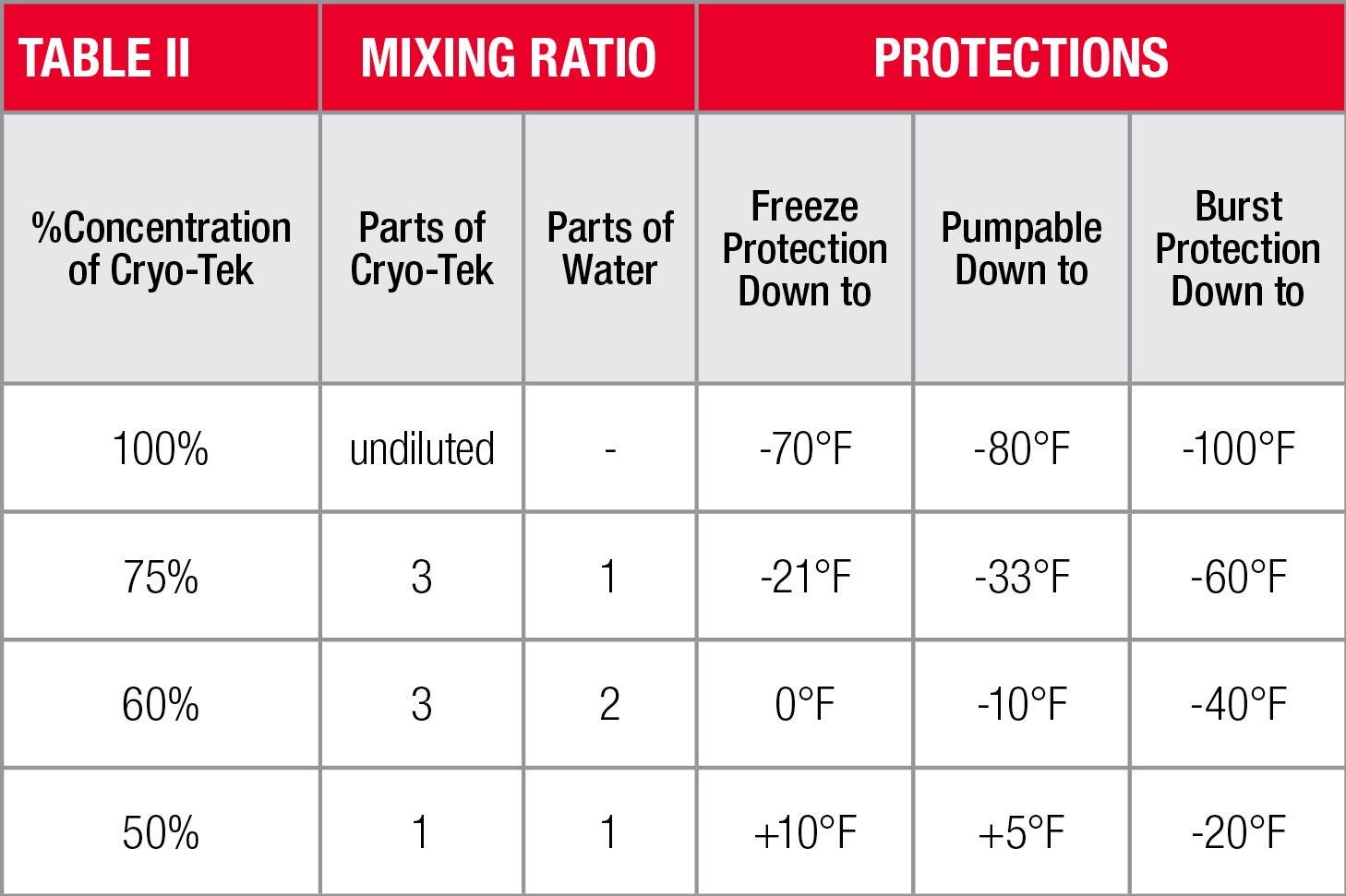

Now it is time to determine the desired temperature coverage for your system. Using Table 2, determine the desired protection level and match it to the appropriate Cryo-Tek product concentration.

Note: The percentages listed in the table refer to the amount of Cryo-Tek solution and not the actual percentage of glycol. (For example: 50% of the -100 is 27.5% glycol)

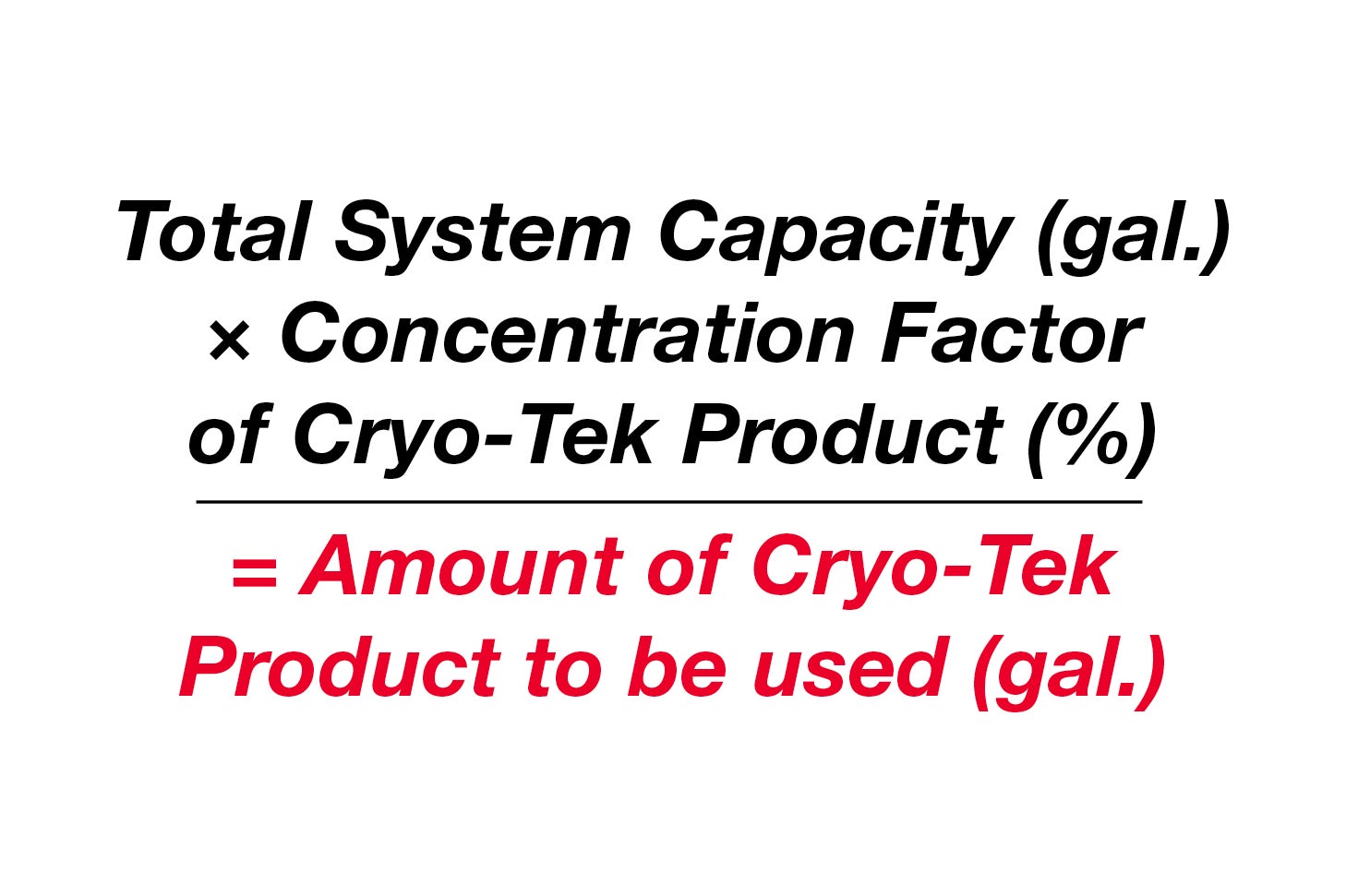

Step 4. Determine Amount of Cryo-Tek Product Required in System

Now it is time to determine the desired temperature coverage for your system. Using Table 2, determine the desired protection level and match it to the appropriate Cryo-Tek product concentration.

Note: The percentages listed in the table refer to the amount of Cryo-Tek solution and not the actual percentage of glycol. (For example: 50% of the -100 is 27.5% glycol)

Step 5. Charge the System

Next, it is time to charge your system with the anti-freeze. The system should be completely empty with the burner and pump shut off. All internal valves, including zone valves, should be open.

Note: THE ENTIRE SYSTEM SHOULD BE OPEN TO PREVENT ANY AREA OF IT FROM BEING ISOLATED.

Add the amount of Cryo-Tek product calculated in Step 4. If the Cryo-Tek solution does not completely fill the system, add water. The system can be filled using one of the following two alternatives. The main objective is to fill the system with little or no air trapped in it.

A. After providing for an air exit, pump solution into boiler through the boiler drain valve using a small pump OR

B. Pour solution through a removed air vent at the HIGHEST point in the system.

Step 6. Purge the Air in the System

Air (which includes oxygen) trapped in a system can result in inefficiencies in the operation of the system (wasted energy and excessive noise), and cause corrosion. To prevent this, the system, once filled, needs to be purged of all air.

When you are filling the system, open another access point or valve that allows the air to escape. Keep this access point open until liquid starts to come out of the system.

Note: Make sure to follow your system manufacturer’s procedures for this step.

Step 7. Test the System

Once installed and fully operational, it is crucial to test the system’s product concentration and inhibitor levels annually. Use Hercules Cryo-Tek Test Strips to test the fluid and ensure proper freeze and corrosion protection.

Note: Automotive coolant tester will not work with Cryo-Tek or other propylene glycol anti-freeze mixtures.

Step 8. Maintenance

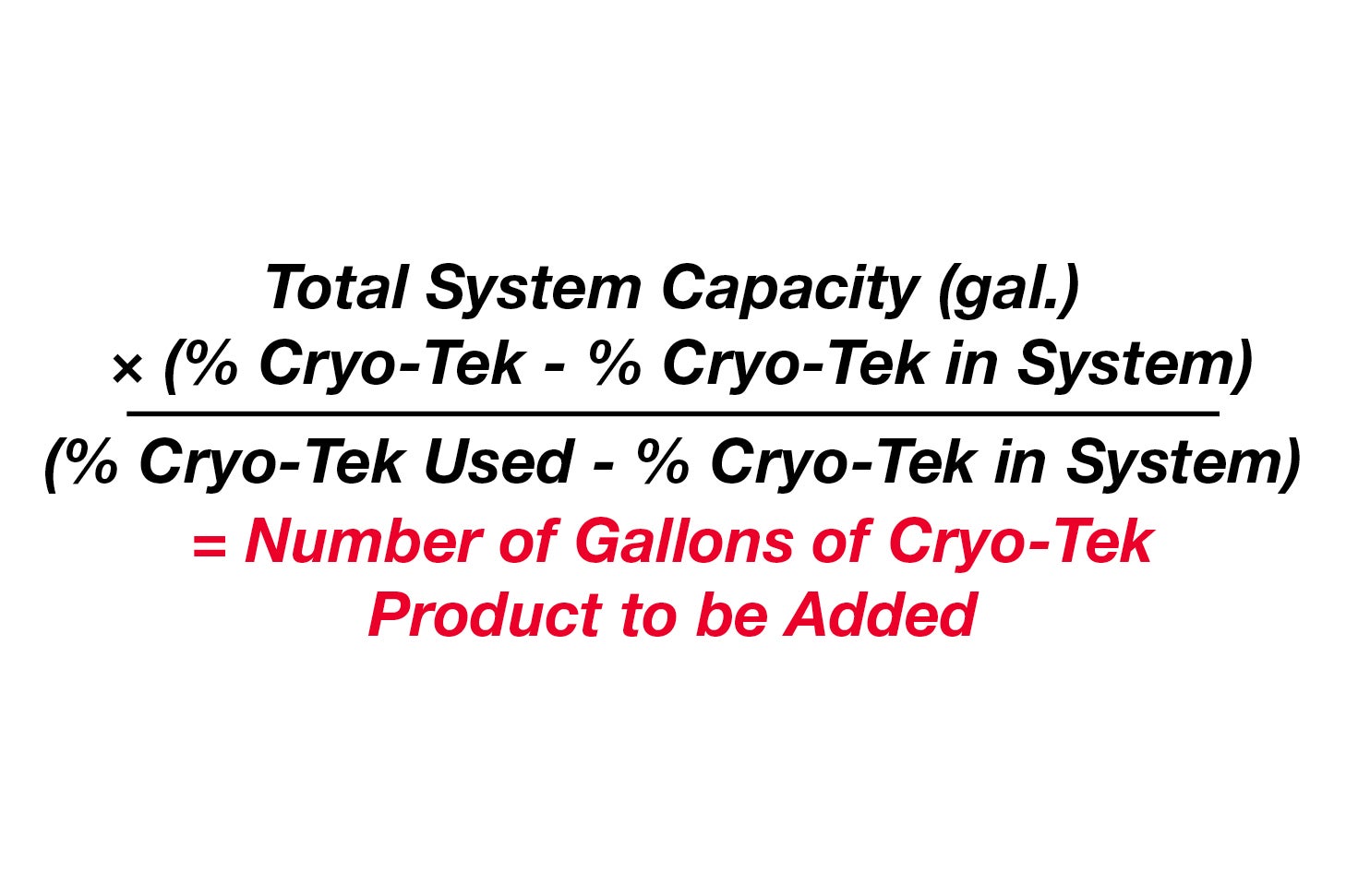

Once tested, if the Cryo-Tek product concentration levels are low, add Cryo-Tek products using the following formula:

If the corrosion inhibitor tests low, add one 8 oz. container of Cryo-Tek inhibitor for every 20 gallons of system fluid capacity. If the total system capacity is less than 20 gallons, add one 8 oz. container of Cryo-Tek Inhibitor. If, after inhibitor addition and thorough system mixing, the corrosion inhibitor still tests low, add another 8 oz. container of Cryo-Tek inhibitor for every 20 gallons of system capacity. If, after this addition, the inhibitor still tests low, the system should be drained, cleaned and recharged with fresh Cryo-Tek.

Remember to always check with the boiler manufacturer for correct glycol levels.

Please contact Oatey technical support at technical@oatey.com for any additional information or assistance.

Extend the life of your hydronic heating system and ensure reliable performance throughout the harshest weather conditions. Rely on Hercules Maintenance and Stop-Leak Products, formulated for high performance and developed with both the user and the environment in mind.

For more ways to extend the life of your boiler check out our blog 4 Tips To Extend The Life Of A Boiler: Seasonal Boiler Maintenance Can Help Your Residential Customers Improve Efficiency And Performance, Year-Round.