Whether you’re a seasoned contractor or a do-it-yourself homeowner, understanding the role of a shower pan, its materials, and installation considerations is key to creating a watertight, durable shower space that stands the test of time.

This blog covers the importance of shower pans, their types and materials, installation considerations, and waterproofing methods essential for creating a durable and watertight shower space.

What is a Shower Pan?

A shower pan is a waterproof floor system that directs water toward the drain, preventing leaks into the surrounding structure. It serves as the base of your shower—not only providing a surface to stand on, but also protecting your home from mold, rot, and costly water damage.

Shower pans play a crucial role in ensuring proper drainage and keeping moisture away from subfloors and walls. When installed correctly, they support the tile or stone layer without shifting or cracking, often lasting for decades, sometimes even outlasting the tiles themselves.

Thus, the underlying layers are as important as the visible surface for a durable and safe shower installation.

Shower Base vs. Shower Pan

Many use the terms shower pan and shower base interchangeably, but there’s a subtle difference:

- A shower base typically refers to a prefabricated, one-piece unit, usually made of fiberglass or acrylic. It’s set in place and connected to a drain pipe, offering a fast and relatively simple installation.

- A shower pan, on the other hand, is built on-site and typically involves multiple layers: a pre-sloped surface, a waterproof membrane (such as a shower pan liner), mortar, and finally, tile or stone. This makes it more customizable for size, shape, and finish.

Both serve the same function—creating a waterproof shower floor. However, their build methods and use cases differ significantly.

Types of Shower Pans and Materials

Shower pans or bases can be made from several materials, each suited to different project needs:

Preformed Bases

Preformed bases are mass-produced in standard sizes, like 60 inches x 30 inches, and are often available in white. While quick to install and great for tight timelines, they offer limited customization options. Preformed bases are ideal for standardized remodels and secondary bathrooms with tight spaces.

- Materials: Fiberglass, acrylic, or composite

- Advantages: Easier and faster to install; ideal for standard-size remodels

- Limitations: Limited shapes, colors, and sizes; less customizable

- Best for: A standard-size opening or shower layout, quick renovations, smaller budgets, and DIY-friendly projects

Custom Tile Shower Pans

Custom Tile Shower Pans are built from scratch and include layers such as a pre-sloped surface, a waterproof membrane, a mortar bed/customizable pans, thin-set, and tile or stone.

- Materials: Mortar, foam systems, tile, stone, or even concrete

- Advantages: Fully customizable for any shape or size; compatible with a wide range of finishes

- Limitations: More complex installation, requiring skill and time

- Best for: Unique plumbing configurations and shower size, layout, or corner configurations, zero-entry or ADA-compliant shower builds, tub-to-shower conversions or high-end spaces

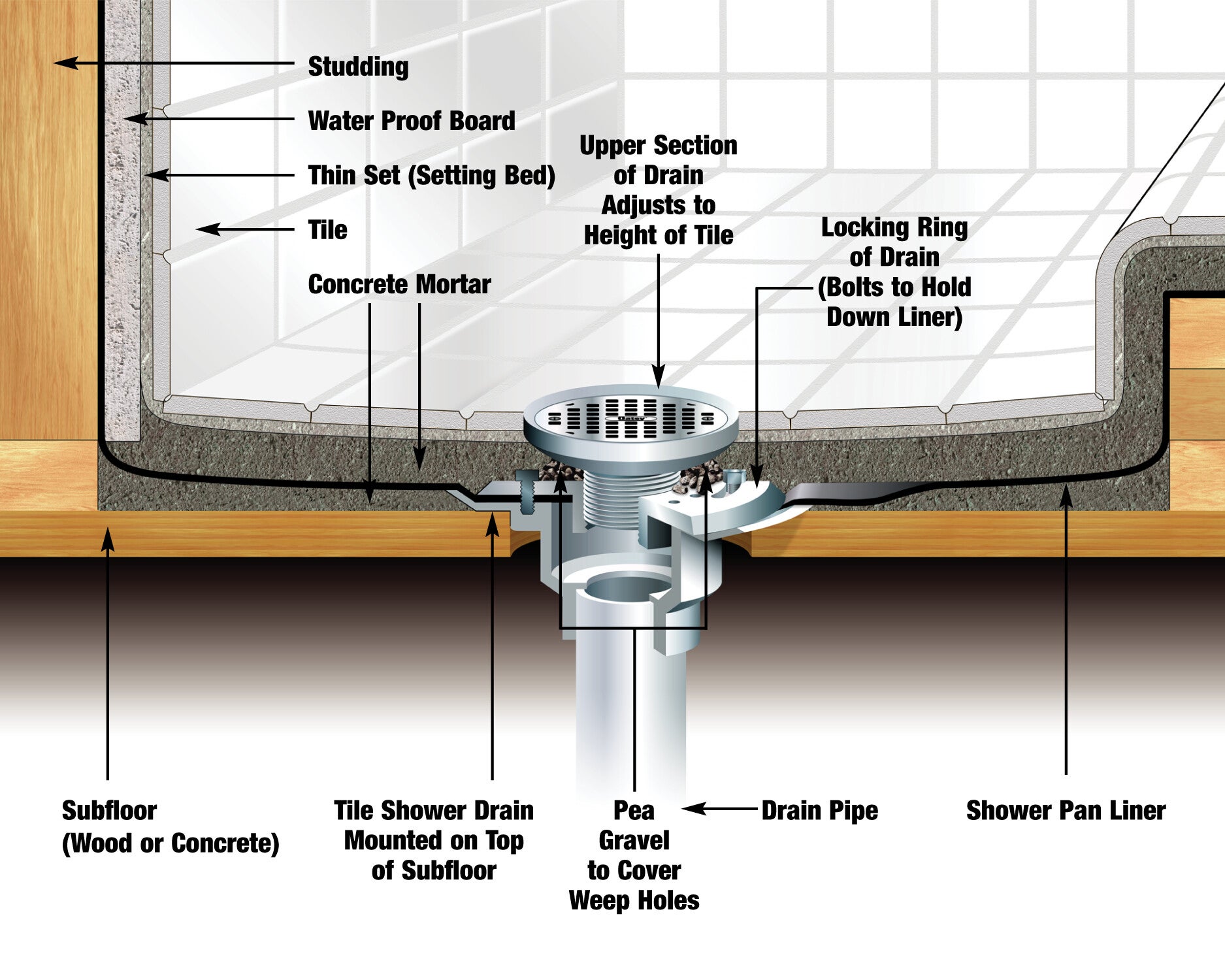

Shower Pan Installation: Custom Tile Shower Pan Layers

Subfloor

The subfloor ensures structural and adequate support. The subfloor must meet TCNA (Tile Council of North America) standards for stability. Inadequate support can lead to cracking and failure of the waterproofing layer.

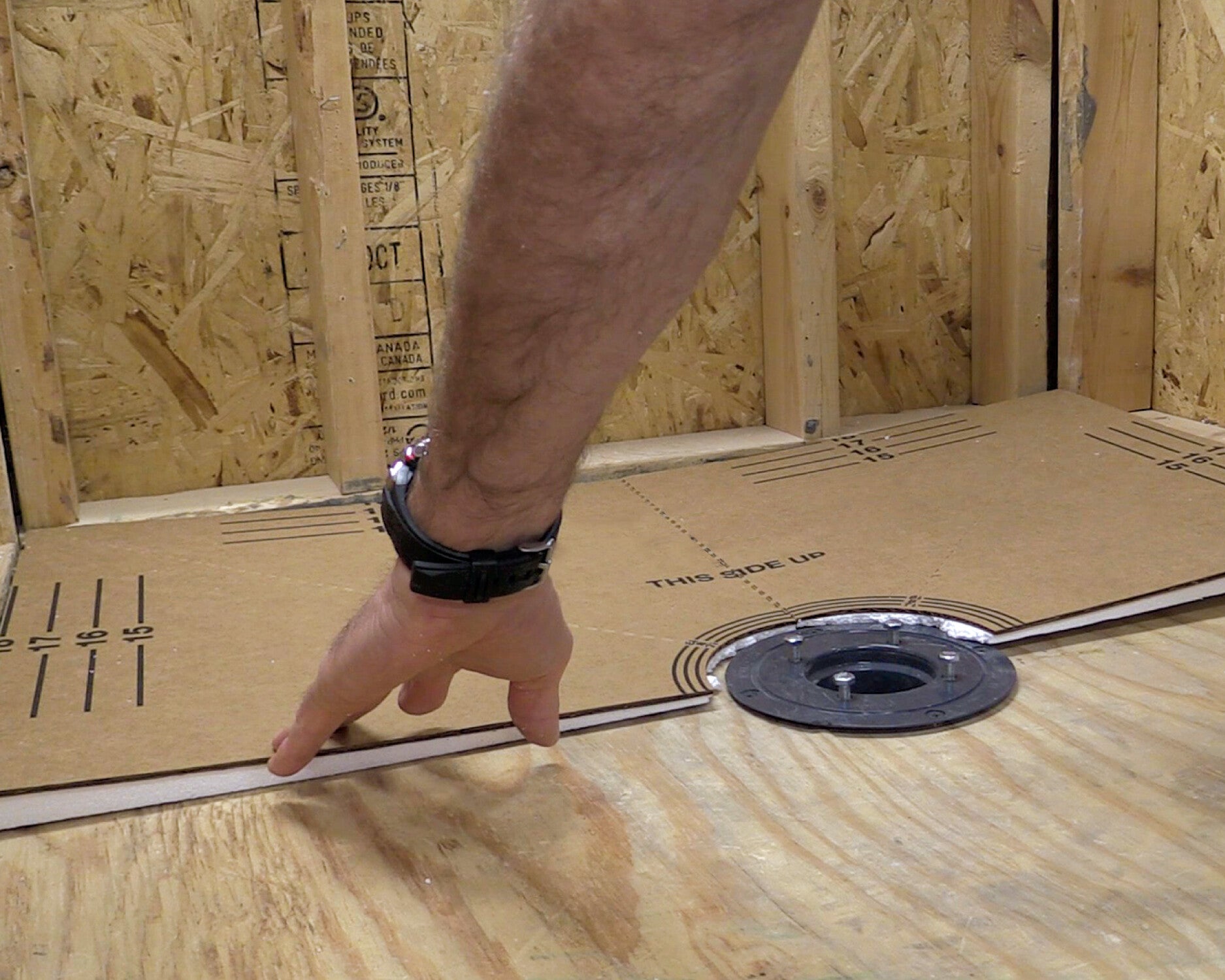

Pre-slope Mortar Layer or Perfect Slope

A pre-slope is implemented beneath the waterproof membrane to direct water into the drain, preventing pooling. Oatey Perfect Slope can help make the process stress-free and efficient. It allows you to install a perfect tile shower pre-slope, requiring half the mortar and half the time. Keep weep holes in the drain assembly clear to allow trapped water to escape.

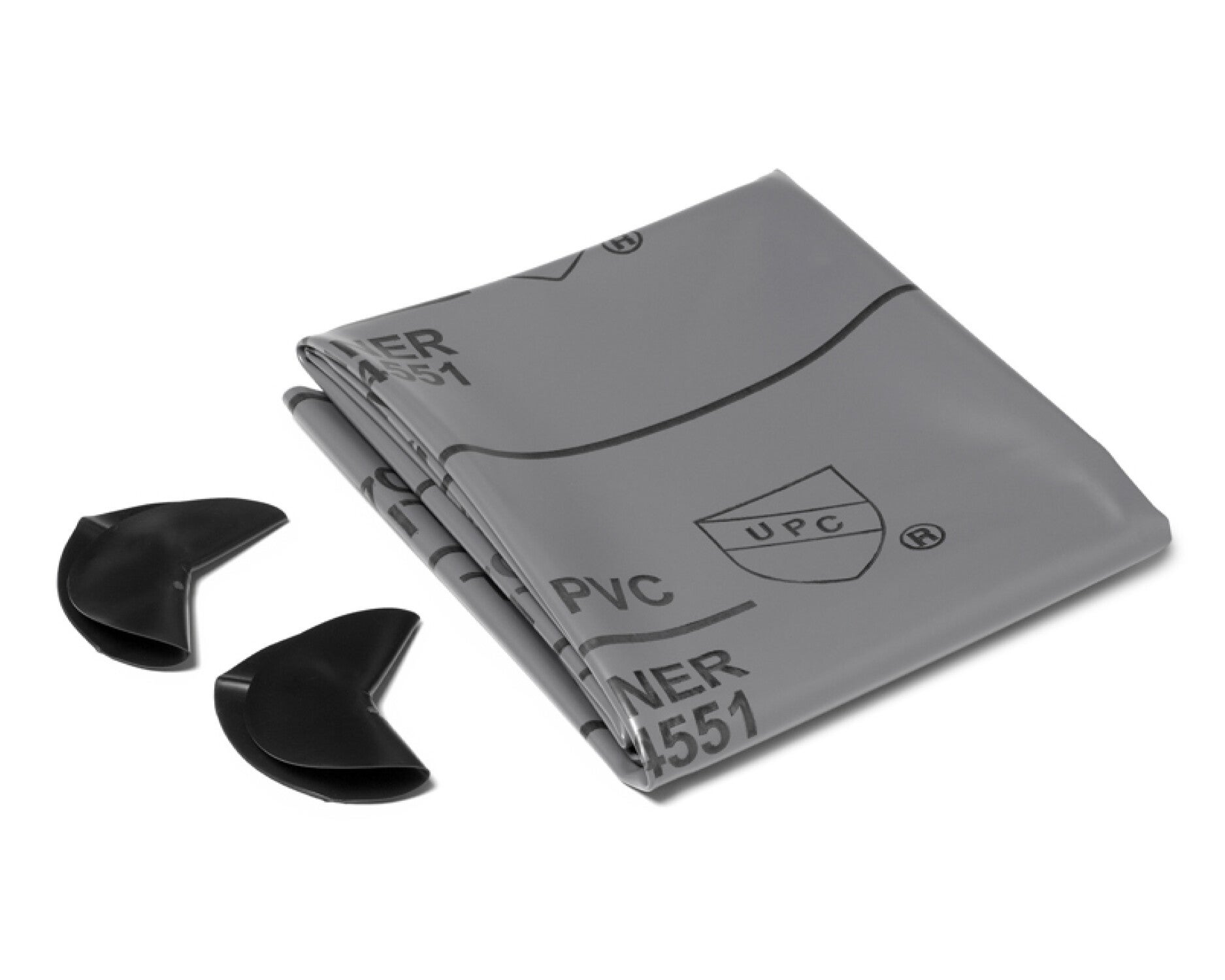

Waterproofing

The shower pan liner is a critical waterproofing layer installed beneath the tile or finished surface. It captures any water that seeps through the grout and redirects it to the drain via weep holes.

The Oatey PVC Shower Pan Liner Kit provides a reliable foundation for a tile-ready, waterproof shower base. The kit includes an economical, flexible pan liner designed to provide a waterproof seal to tile shower bases and for other concealed waterproofing applications. Made of abrasion-resistant PVC material for long-lasting use, it is marked on the back in six-inch increments to allow easy measuring and trimming.

This kit also includes two Oatey PVC Dam Corners: preformed, flexible corners designed to seal the junction of the curb and door jamb.

Other waterproofing methods:

- Liquid waterproofing

- Fabric liners

- Hot mop

The waterproofing layer is non-negotiable, regardless of type. From traditional PVC liners to modern fabric systems like QuickDrain Sheet Waterproofing Kits or liquid waterproofing membranes, the key is selecting a method that suits your shower design and skill level.

Need help choosing or installing your waterproofing system? Whether you're leaning toward a PVC liner or exploring modern alternatives, Oatey has you covered. Dive into our step-by-step guide to installing a shower pan liner or read more about different shower waterproofing methods.

Mortar Bed or Customizable Pans

A mortar bed is a layer of mortar spread over the shower surface and sloped to the drain, typically to create a stable base for laying tiles or stones. It helps ensure even support and proper adhesion, providing a level surface for the installation.

An alternative to costly, time-consuming mortar beds is customizable pre-sloped shower pans, such as QuickDrain PET foam pan kits. These kits, made from recycled polyethylene terephthalate water bottles, reduce installation time by two days compared to traditional dry-pack mortar beds, and are ready to leak test in as little as 2 to 3 hours. The pre-sloped shower pans eliminate the need to float the pitched mud bed and wait for it to cure, saving big on labor costs.

With various styling options and superior installation flexibility, QuickDrain’s PET foam pan kits used with QuickDrain linear drains enable wall-to-wall coverage that promotes effective and efficient water drainage. The foam pans are site-sizeable with a utility knife for easy modification and flexibility.

Designed for use with ShowerLine Drain Kits, the QuickDrain ShowerLine Installation Kit includes a 32-inch x 64-inch, pre-sloped shower pan with curb and liquid waterproofing accessories. Provided inside corners, curb covers, and reinforcement fabric create a waterproof seal over joints, transitional seams and plane changes in the shower pan.

These foam pan kits can also be used with QuickDrain square drain systems.

Thinset and Tile or Stone Finish

Thinset is a cement-based adhesive for bonding tiles to a substrate in shower installations. It provides a strong and durable bond, helping to stabilize the tiles and prevent cracking or shifting. Thinset is typically applied in a thin layer between the tile and the surface.

Choosing the best shower pan depends on your space, budget, skill level, and design goals. Whether you opt for a standard prefab base or a custom tile-ready system with a high-performance liner, the most critical factors are proper slope, precise waterproofing, and attention to detail.