Picking the right piping material can make all the difference in durability, safety, and long-term performance. A common question concerns the key differences between CPVC and PVC pipe. Understanding those differences will help ensure you’re using the best option for the job, whether for a home project or something on a larger scale.

If you’re unsure what distinguishes CPVC from PVC, you’re not alone. This guide will break down the differences in a straightforward manner.

What is CPVC Pipe?

CPVC (Chlorinated Polyvinyl Chloride) is a thermoplastic pipe material known for its high-temperature resistance and superior chemical durability. It is created by adding chlorine to standard PVC, enhancing its strength, heat tolerance, and ability to withstand aggressive chemicals.

What are the Benefits of CPVC Pipe?

- Higher temperature resistance: CPVC is rated for up to 200° Fahrenheit, compared with PVC’s 140°F limit.

- Stronger chemical resistance: CPVC is more resistant to acids, bases, and salts, making it ideal for industrial applications.

- Safe for hot water applications: Unlike PVC, CPVC pipe for hot water is commonly used in both residential and commercial settings.

- Durable, long-lasting: CPVC offers greater resistance to cracking and corrosion over time.

What are the Differences Between CPVC vs. PVC?

While both PVC and CPVC are used in various plumbing and industrial applications, their differences make them suited for specific uses, as outlined in the accompanying chart.

- If your system requires hot water, CPVC is the better choice.

- For cold water or drainage, PVC is often sufficient.

- Industrial settings with aggressive chemicals favor CPVC.

CPVC vs. PVC Comparison Chart

| Feature | CPVC | PVC |

|---|---|---|

| Temperature Rating | Up to 200°F | Up to 140°F |

| Color | Typically yellow, off-white, or gray | Typically white |

| Chemical Resistance | Resistant to strong acids and bases | Less resistant to certain chemicals |

| Applications | Hot and cold water supply, industrial piping, chemical drainage, fire suppression | Cold water systems, drainage, irrigation |

| Joining Method | Solvent welding with CPVC-specific cement | Solvent welding with PVC cement |

What are Common Uses of CPVC Pipe?

CPVC’s unique properties make it a preferred choice in various industries and residential applications.

1. Residential Plumbing

- Hot and cold potable water supply

- Replacement for copper pipes due to cost-effectiveness and corrosion resistance

2. Commercial and Industrial Applications

- Fire suppression systems (e.g., BlazeMaster® CPVC)

- Chemical processing and waste drainage

- High-temperature exhaust and boiler applications

3. HVAC Systems

Used in certain air handling and cooling systems due to heat resistance.

Best Practices for CPVC Installation

1. Use the Right Solvent Cement

CPVC requires a specific cement that ensures strong, leak-free joints. FlowGuard Gold® 1-Step Cement or Oatey® Orange Lava are commonly used to provide reliable, code-compliant bonding solutions for hot and cold water systems.

Using the wrong cement is a common mistake. Avoid it by reading our blog on selecting the best option for your job.

2. Prepare Pipe Properly

- Cut the pipe squarely: Make clean, straight cuts for a secure fit.

- Chamfer and deburr the edges: Smooth the edges to prevent cement blading during assembly.

- Use primer when required: Always apply primer on the pipe and fitting if the manufacturer’s instructions recommend it for a stronger bond.

- Use the right amount of cement: Apply enough cement to completely cover the pipe and fitting surfaces without overfilling. Too little cement can result in weak joints, while too much can puddle, potentially weakening the joint and leading to leaks. Ensure the cement is evenly spread, but avoid excess.

3. Avoid Dry Fitting

Dry fitting without cement can lead to forgotten joints, increasing the risk of leaks or failure. To help prevent this, Oatey FlowGuard™ High Contrast 1-Step Medium Green Cement’s green color provides high contrast to CPVC pipe, making it easy to identify applications.

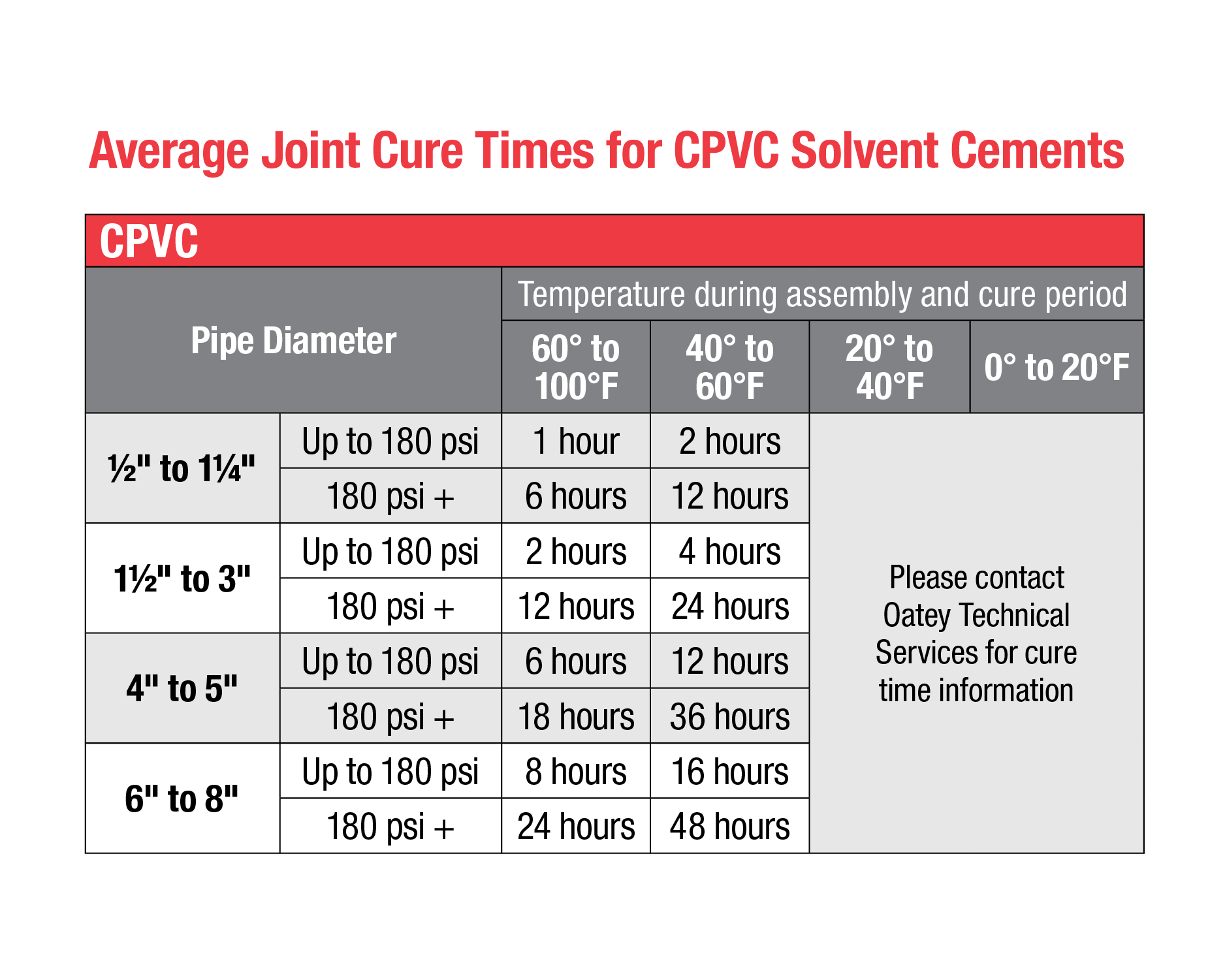

4. Allow Proper Cure Time

CPVC solvent cement takes longer to cure than its PVC counterpart due to the former’s deeper chemical penetration. Always follow the recommended cure time chart.

5. Ensure Adequate Support

CPVC pipes need proper bracing and support to prevent sagging, especially in high-temperature applications.

6. Provide Proper Ventilation

During installation, it's important to avoid sealing off the system too quickly, as you want the solvents to evaporate. The curing process relies on the solvents evaporating to form a strong bond.

How Do You Choose Between CPVC and PVC?

When deciding between CPVC and PVC, consider the following:

- If your system requires hot water, CPVC is the better choice.

- For cold water or drainage, PVC is often sufficient.

- Industrial settings with aggressive chemicals favor CPVC.

- Fire suppression systems require CPVC due to its high-temperature resilience.

FAQs

Can CPVC and PVC be used together?

Yes, but a transition fitting is required to connect them properly. CPVC and PVC require different types of solvent cement, so it's essential to use CPVC cement for any one-time transition.

Is CPVC safe for drinking water?

Yes, CPVC is approved for potable water use and is resistant to biofilm growth, making it a safe choice for drinking water systems.

Why is CPVC more expensive than PVC?

CPVC undergoes an extra chlorination process, which increases its durability and heat resistance. This additional treatment makes it slightly more expensive than standard PVC.

How long does CPVC pipe last?

CPVC piping can last 50 years or more with proper installation and maintenance. Factors such as water chemistry and environmental conditions may affect longevity.

Does CPVC need special tools for installation?

No special tools are required beyond standard cutting and deburring tools. However — once again — CPVC requires CPVC-compatible solvent cement for proper bonding.

The Oatey® Purple Primer & CPVC Cement Handy Pack streamlines your workflow with everything you need for a strong, code-compliant CPVC bond in one package. No wasted time — just prep, cement, and move on to the next job.