Threaded pipe connections need sealant because they are not leak-proof by themselves. Tiny gaps between threads can allow water, gas, or air to escape. To prevent leaks, professionals and DIYers use pipe thread sealant to create a secure connection.

Thread sealant tape, also known as plumber’s tape or Teflon (PTFE) tape, is a thin, flexible tape used to seal threaded joints. Another option is pipe joint compound, also called pipe dope, which is brushed into the threads as a paste.

This guide will help you choose and apply the right sealant. It explains the differences between plumber’s tape and pipe dope, when to use each one, and how to apply pipe thread sealant properly for leak-free joints.

When to Use Thread Sealant Tape or Compound

Choosing the appropriate type depends on the job requirements, pipe material, chemical exposure, and temperature conditions.

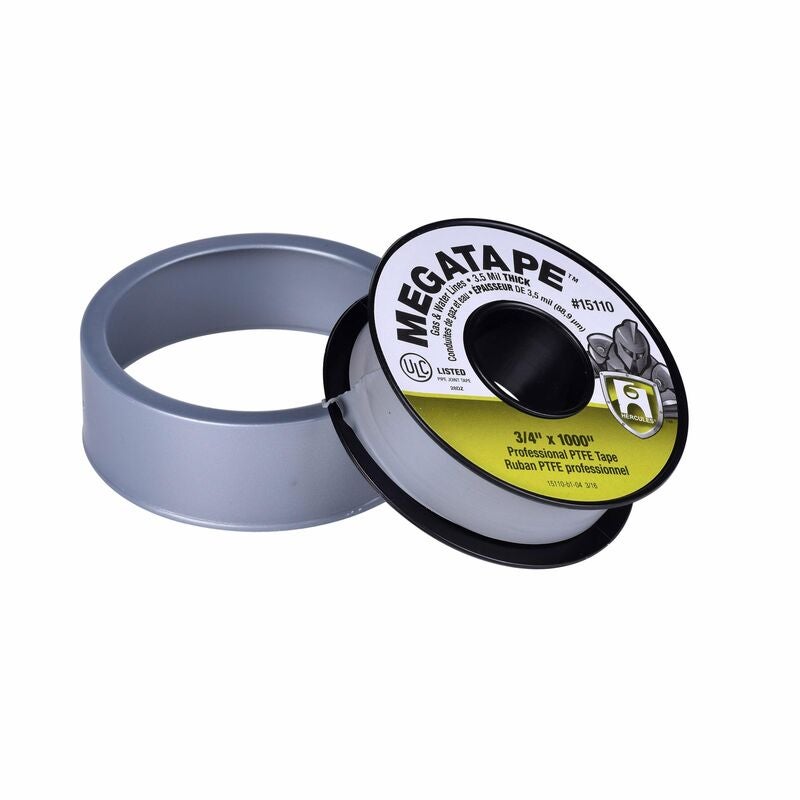

Thread Sealant Tape, like Hercules® MegaTape, comes in a variety of colors, widths, thicknesses, and densities:

Thread Sealant Tape, like Hercules® MegaTape, comes in a variety of colors, widths, thicknesses, and densities:

- Color: Use yellow tape for gas applications when required by code. Choose white or gray tape for general plumbing. Opt for gray when matching the pipe color for a cleaner look.

- Width: Use half-inch tape on small-diameter pipe. Use three-quarter-inch or 1-inch tape on larger diameters.

- Thickness (mil): Higher thickness reduces the number of wraps needed to seal the threads.

- Density: High-density tape compacts better and resists stretching during assembly, which helps maintain a reliable seal.

Pipe Joint Compounds, such as Hercules® Megaloc® and Hercules® Pro Dope®, should be selected based on three key factors:

- Material compatibility: Check the product label or submittal sheet to ensure the pipe and fitting materials are compatible. Incompatible combinations can cause deterioration and failure.

- Chemical compatibility: Ensure the compound resists the types of chemicals in the system. Prolonged exposure to incompatible chemicals can break down the compound over time.

- Temperature performance range: Two temperature ratings apply. One is the brushability temperature, which indicates the range in which the product can be applied. The other is the performance range, which indicates operational limits after application. This information is available on each product’s submittal sheet at www.oatey.com/products/thread-sealants

When Should You Use Plumber’s Tape vs Pipe Dope?

| Feature | Thread Sealant (Tape | Plumber’s or PTFE Tape) |

Pipe Joint Compound | Pipe Dope |

|---|---|---|

| Best For | DIY projects, quick jobs, smaller-diameter fittings | Large fittings, pros, high-pressure systems, and preferred for water systems. |

| Advantages | Clean, easy to use, fast application | Fills voids thoroughly, withstands higher temperatures and pressures, |

| Disadvantages | Can unravel if misapplied | Messier, requires cure time for high-pressure systems |

If you are wondering when to use thread tape versus joint compound, the general rule is that tape works best for small and medium fittings, while compound provides extra sealing strength for larger or pressurized joints. Both can be used together on any joint per installer preference.

How to Apply Thread/Teflon Tape vs. Compound/Pipe Dope

How to apply pipe thread sealant tape:

- Always apply thread sealant tape to male threads to prevent material from entering the system.

- Choose the correct tape (width, thickness, density). Then start wrapping on the second thread, leaving the first exposed to avoid contamination.

- Wrap clockwise three to five times to match the tightening direction and prevent unraveling. As the joint is tightened, the tape compresses into the thread roots, conforming to the pattern.

- Finally, smooth the tape into the threads for a neat finish and reliable seal.

For a detailed, step-by-step guide on sealing threaded pipe joints, visit our complete guide to using thread seal tape.

How to apply pipe thread compound:

- Apply only to male threads to keep the compound out of the pipe interior.

- Stir the compound before use for a uniform consistency.

- Brush on a thin, even coat across the threads, but not along the thread path, to ensure full coverage.

- Leave the first thread bare to prevent excess from entering the system.

Assemble and tighten the joint; excess compound will push outward, leaving a clean, sealed connection.

Common Thread Sealant Application Issues and Fixes

| Problem | Cause | Fix |

|---|---|---|

| Leak at the joint | Under-tightened, not enough sealant, or defective threads | Disassemble, clean, reapply, and retighten |

| Tape bunching or tearing | Wrapped in the wrong direction | Rewrap clockwise only |

| Threads do not tighten | Too much tape or defective threads | Remove excess tape or replace the fitting or pipe threads |

| Sealant clogging gas orifices | Tape extended too close to the first thread | Always leave the first thread bare |

| Overtightening | Excessive torque is causing cracks | Use hand-tight plus one or two wrench turns |

Pro Tips for First-Time DIYers

- Don’t overtighten: This is one of the most common mistakes. Hand-tightening, followed by a wrench turn or two, is usually enough.

- Check your tools: If you’re cutting your own threads, dull pipe dies can create defective threads that leak, no matter the sealant.

- Practice makes perfect: Like most plumbing skills, sealing threads well is a skill you develop over time.

Frequently Asked Questions

-

What’s the best thread sealant for plumbing: Plumber’s tape or pipe dope?

-

Both work well. Tape is more versatile and less messy; compound offers durability and better performance on large or industrial connections. Most pros prefer tape for everyday use.

-

-

How many wraps of Plumber's tape should I use?

-

Use 3–5 wraps of standard white tape or 2–3 for dense, professional-grade options like MegaTape.

-

-

Is thread sealant safe for gas lines?

-

Yes. Yellow tape is often preferred (and may be code-required), but all PTFE tapes are generally inert and gas-safe. Check with local code.

-

-

What’s the shelf life of each type?

-

PTFE tape lasts indefinitely. Pipe dope can dry out and should not be used after its manufacturer’s expiration date.

-