The art and science of welding go beyond metals and soldering tools to also include using primer and cement to bond two plastic surfaces together molecularly. Let’s explore these two products and the factors that should be considered before performing a solvent weld.

What is solvent cement?

By definition, cement is a permanent application that conducts chemical welding of two PVC, ABS or CPVC pipe surfaces together. Once the cement is applied to the top layer of a pipe surface and inside the fitting, the layer softens and dissolves. When cured, the surfaces fuse into one, creating an air-tight seal.

Oatey offers solvent cement products for a variety of commercial and residential applications, including potable water, DWV (drain-waste-vent), industrial, pool/spa, turf/irrigation, sewer and many more.

When choosing a solvent cement for your application, consider the following factors and products:

Materials: Identify the piping material being fused to select the corresponding cement.

- ABS: For example, the Hercules® ABS Medium Body Black Cement should be used only on schedules and classes of ABS pipe and fittings. This cement is perfect for non-pressure applications and contains a low VOC.

Oatey® Special Medium Milky Clear ABS Cement is also recommended for non-pressure applications. Fast setting, it can be used to solvent-weld all schedules and classes of ABS pipe and fittings up to 6-inches in diameter with interference fit. This milky-clear formula eliminates the cleanup that other colored cements can present.

- PVC: The same concept applies to PVC solvent cement. The Oatey® PVC Medium Bodied Fast Set Clear Cement can be used on all schedules and classes of PVC pipe and fittings, particularly for the DWV system, pressure pipe, potable water and electrical applications.

Hercules® Clear Heavy Body Slow Set Cement is applicable for potable water, pressure pipe, conduit, and DWV applications. It can be used to solvent-weld PVC Schedule 40 and 80 and up to 18 inches in diameter with interference fit.

- CPVC: For CPVC applications, products such as the Hercules® CPVC Medium Bodies Fast Set Orange Cement are intended for CPVC Schedule 40 and 80 pipe and fittings for potable water, DWV and SW pipe applications.

Oatey’s FlowGuard™ High Contrast 1-Step Medium Green CPVC Cement contains a vivid green color indicating a properly solvent-welded connection while simultaneously identifying pipe fittings that lack solvent welding and, therefore, can cause blowouts during system testing. Recommended for cold and hot water systems up to 200℉

- All-purpose: An all-purpose cement, such as the Oatey® All-Purpose Clear Cement, is applicable for solvent welding of all schedules and classes of ABS, PVC, and CPVC pipe and fittings used for DWV, potable water and irrigation applications.

Hercules® Multi-Purpose PVC-CPVC Medium Body Fast Set Cement, recommended for potable water, conduit and DWV applications, can also be used to solvent-weld PVC, CPVC, and ABS Schedule 40 and 80 up to 6 inches in diameter with interference fit. This cement is fast-setting with a milky-white appearance.

Pipe size: The larger the pipe and fittings, the larger the gaps between the two surfaces. Different viscosities of cement are available to accommodate the different sizes of pipes and fittings to adequately fill the gaps for secure and successful welding.

Regular-body cement, such as the Hercules® Clear Cement, can weld up to 4 inches in diameter with interference fit for non-pressure applications and up to 2 inches for pressure applications.

Medium-body cement, like the Hercules® Multi-Purpose Fast Set Cement, is applicable for pipes up to 6 inches in diameter with interference fit, compared with a heavy-bodied cement that can weld an interference fit up to 12 inches in pressure applications and 18 inches in non-pressure applications.

Extra heavy-bodied cement is required for applications that require solvent welding for pipes up to 24 inches in pressure applications or up to 30 inches in non-pressure applications. Oatey carries an 1800 Series Super 30® PVC Cement formulated for potable water, sewer and DWV systems. It is ideal for pipe fabrication and large-diameter installations.

External conditions: Regarding temperatures, three factors come into play: application temperature, use temperature, and cure temperature.

— Application temperature: Most cements have a maximum application temperature of 110℉and an average minimum temperature for application set at 40℉. Keep in mind that cement in a warmer environment keeps the cement consistency fluid.

All-weather cements, such as Oatey® All Weather PVC Cement, are available for application temperatures from -15℉ to 110℉, allowing the cement to remain free-flowing. Once temperatures drop below -15℉, the cement begins to crystallize and freeze.

The Oatey® Uni-Weld 2600 Series Polar-Weld™, recommended for potable water, pressure pipe, and DWV applications, is formulated to set quickly in temperatures as cold as -15℉.

— Cure temperature: Looking at the overall project, remember that the warmer the conditions, the faster the cure. Conversely, colder temperatures will mean longer cure times.

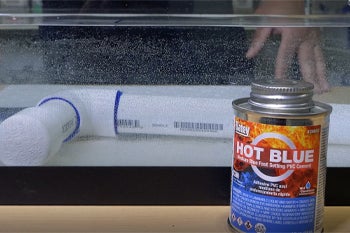

— Wet conditions: Specially formulated cements are available for wet conditions and quick pressurization. Some service work may require cutting into an existing pipe whose flow can be shut off only partially. Cements such as Oatey® PVC 2400 Series Turf-Tite “Hot” Blue Cement are recommended for potable water, pressure pipe, and DWV applications.

For irrigation, pool and spa, and DWV applications, the Oatey® Hot Blue Medium Blue Fast Setting PVC Cement can also be applied in wet conditions. This cement can solvent-weld all scheduled and classes of PVC pipe and fittings up to 6 inches with interference fit.

Viscosity is the measurement of flow resistance in a fluid. High viscosity would refer to a thicker liquid with greater flow resistance. Low viscosity refers to a fluid that offers lesser friction and resistance.

Viscosity in cement ranges from regular body, such as the Harvey™ C-4 CPVC Cement, to heavy-duty, like the Oatey® Heavy Duty Orange CPVC Cement.

What is primer?

Before the cementing process can begin, first apply primer. Not only does primer remove surface dirt, grease and grime, but — as noted previously — solvents within the primer itself soften the pipe, dissolving into and separating the pipe’s surface molecules. As a result, the surface becomes more porous, allowing for a fast and secure solvent weld.

A variety of primers are available and applicable to certain applications. Below are a few factors to keep in mind when applying primer.

Material: Primer can be applied only to PVC and to CPVC applications, not to ABS pipe. Some primers, such as the Hercules® Purple Primer, can be used for both PVC and CPVC. Local codes may require using the purple primer to identify the proper application easily.

In addition, the Hercules® Un-Purple Primer may finish clear. But under a UV light, the purple tint will appear to indicate the use of primer during the solvent-welding process.

Oatey’s Industrial Grade Clear Primer is a more aggressive primer applicable for commercial and large diameter thermoplastic piping systems. This primer is applicable for solvent welding PVC and CPVC pipe and fittings and contains a clear finish.

Maximum Application Temperature: When applying primer, the maximum application temperature is 110℉.

Primer and cement application: When applying primer, use a heavier, more aggressive application to ensure that solvents are worked into the surface. Remember that the use of primer is to break down that surface tension.

The primer should be applied to the fitting using an applicator, such as the Oatey® Adjustable Plastic Dauber. Apply the primer to the fitting, and then re-dip the applicator to apply to the pipe. Then, re-dip the applicator one more time and apply it again to the fitting itself.

Within five minutes, apply the cement while the primer is still wet. Oatey offers a handy pack containing primer and cement for smooth installation and convenient storage.

For an in-depth video on the application of primers and cement, click HERE.

Frequently asked questions

FAQ 1: What PVC cements allow for the longest setup time in multiple-joint assemblies?

Heavy-duty cement, such as the Oatey® EP-42 CPVC HD Gray Industrial Cement, has a slow setup time before the joint is assembled due to the slow evaporation process. But this cement type also has the shortest working time once the joint has been assembled.

FAQ 2: What cements allow for the shortest setup time in multiple-joint assemblies?

Regular body cement, such as Hercules® Clear Regular Body Medium Set PVC Cement, has the quickest setup time before the joint is assembled due to its quick evaporation process. Once the joint is assembled, regular body cement has the longest working time.

FAQ 3: What can I use to clean up purple primer?

Purple primer is permanent and cannot be cleaned. Oatey does offer the Un-Purple Primer, as mentioned in this blog. In addition, the Oatey® Clear Primer is available for all schedules and classes of PVC and CPVC pipe and fittings.