Professional tips to ensure leak-free installations and avoid on-the-job accidents

Most homeowners don't associate plumbing work with their roofs. But many roofing contractors, plumbers, and inspectors often need to be on the roof to perform their jobs.

If you're working on your home's plumbing vent, replacing the roof, or just doing an annual inspection, you may need to repair or replace the roof flashing.

What is a roof flashing?

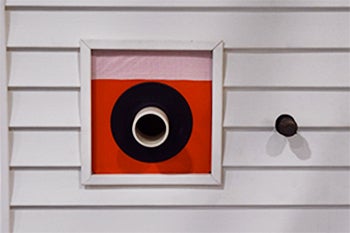

Roof flashings are used to seal some sort of roof penetration. Whether from a vent pipe, an exhaust fan, a skylight, or a chimney, roof flashings will seal and weatherproof a particular area.

But if a roof flashing is not properly installed, there is a risk of leaks. Water can get into the opening and damage not just the roof, but also the walls, drywall, wood, and more inside a home.

Oatey has flashings available in various materials used in commercial and residential applications: thermoplastic, aluminum, galvanized, and copper.

Oatey Master Flash and Retro-Master Flash are rated for continuous temperatures up to 212°F. All other Oatey flashings are rated up to 180°F continuous heat and approved for Type B Installations. Oatey also offers the Master Flash® for commercial applications and various specialty items, including Rain Collars and Mushroom Caps.

It's important to have a solid understanding of how to install flashing products safely and effectively. Follow these best practices to ensure a proper, leak-free installation while staying protected on the job:

What to consider when choosing the right roof flashing

● Pitch (or angle) of the roof. If the home's roof is flat, you must use a flashing that accommodates a 90-degree pipe angle. However, a pitched roof requires an angled flashing and is designed to work with the degree of the pitch.

● Location and climate. To retain its water-tight seal, the flashing must be able to handle the roof's expansion and contraction through various temperatures. It must also withstand constant exposure to UV rays without becoming brittle. If the home is near a saltwater source, the flashing should feature a galvanized base or a coating to help prevent corrosion.

● Vent-pipe diameter. To ensure a water-tight seal, choose a flashing with a properly sized opening for the pipe size exiting the roof. Never try to slide a smaller flashing collar over a larger pipe because it will cause fatigue failure in the collar. Never install a larger collar over a smaller pipe, and try to use sealant to fill the void. Any sizing miscalculations will lead to leaks within the home or building.

● Specialty applications. Some homes will require specialty flashings, such as side flashings. These can be used for plumbing, electrical, and HVAC pipes that exit the side of the home –– rather than through the roof –– or over solar posts. In applications where the integrity of the flashing base is in good shape, but the rubber rain collar is not, Oatey's Rain Collar for No-Calk® Roof Flashings can easily be installed over the existing rain collar to restore its seal.

Types of Oatey Flashing

● Standard Flashings: These are made of aluminum, thermoplastic or galvanized materials, and their self-sealing collars slide over a pipe with no caulking required. They can easily accommodate a broad range of pipe diameters.

● High-Rise® Flashings: For use on a shingled roof with an extreme pitch, the flashing itself will accommodate an angle up to 60 degrees.

● Sideflash™ Vertical Flashings: These are designed to seal around piping, electrical and other-utility penetrations through outside walls. Accommodating pipe sizes from ½" to 2-½" or 3" to 6", vertical flashings can be installed over a house wrap or building paper to become part of the building envelope.

● Master Flash® Flashing: Engineered for metal roof applications for any pitch, these flashings can be easily customized to accommodate a broad range of pipe diameters. They have a 20-year warranty from the date of manufacture.

Step by step guide to install roof flashing

Step 1: Before installing any flashing on an unfinished roof, clean off all debris and apply a waterproof layer of felt or tar to the roof's underlayment (if one isn't already applied). On homes with completed roofs, you will need to pry up the roofing nails used to secure the old flashing, then carefully lift the shingles above the flashing so you can lift the flashing over the pipe.

Step 2: In a new-roof installation, install the shingles starting at the bottom of the roof and move upward to the peak, row by row. Each row should overlap the previous one, so water has no way to penetrate below or between the shingles.

Step 3: As you near the pipe penetration, chamfer the open end of the pipe; that is, give it a beveled edge. Clean the edge and the area around the pipe, and slide the flashing over the chamfered end, so it lays flush against the waterproof underlayment and shingles. Secure the flashing to the roof using roofing nails, ensuring they are under the protection of the shingles to prevent leaks.

Step 4: Once the shingles are fully installed, you can perform a water test by spraying water from a hose onto the roof above the pipe vent. Douse the roof for 15 minutes. Then check the attic space where the pipe exits the home to see if any water leaks. If no leaks are visible, the flashing is water-tight, and the job is complete.

For further instruction on how to properly install roof flashings, watch our video tutorial.

Roof safety guidelines

As with any plumbing installation, safety must be a top priority when installing or repairing roof flashings. Take the following precautions to reduce your risk of having an accident:

1. Tread lightly. Roofs are not designed to handle regular foot traffic. Make sure you tread lightly across any roof you're working on, even for a short period. And don't forget to check weather conditions ahead of time. Wind, rain, snow, and ice can make it harder to maintain footing.

2. Identify hazards. Before work begins, clear the roof surface of any potential tripping or slipping hazards, such as fallen branches, leaves, tools, or other materials. Flag any skylight locations. Depending on the home, you may also need to be aware of overhead power lines, exposed wires, conduits, or solar panels.

3. Stick to the essentials. You will need only a hammer, nails, and flashings when installing. Keep all other tools or materials off the roof. If you are replacing an existing flashing, you will need a flat bar to assist in shingle removal.

4. Practice ladder safety. The ladder you use to get on the roof should be tied off or secured to the building to prevent it from shifting. If that isn't possible, enlist a second person to remain on the ground and hold the ladder in place when you ascend and descend from the roof.

5. Stay hydrated. Because a roof is designed to reflect heat, workers can easily become dehydrated on hot days. Drink plenty of water to avoid dizziness or lightheadedness that may lead to falls and other accidents.

With the exception of the Master Flash and Retro-Master Flash, all Oatey flashings have a one-year warranty from the date of manufacture. Flashings cannot be guaranteed for the roof's life due to varying roof life spans and potentially adverse conditions; i.e., extreme heat, extreme cold, and hail.

Ultimately, the installation of flashings and proper sealants is meant to protect a roof from water damage and unnecessary wear and tear. It's imperative that the flashing expand and contract with the outside elements and divert water off the roof. A proper roofing contractor can check for damage or potential problem areas.